-

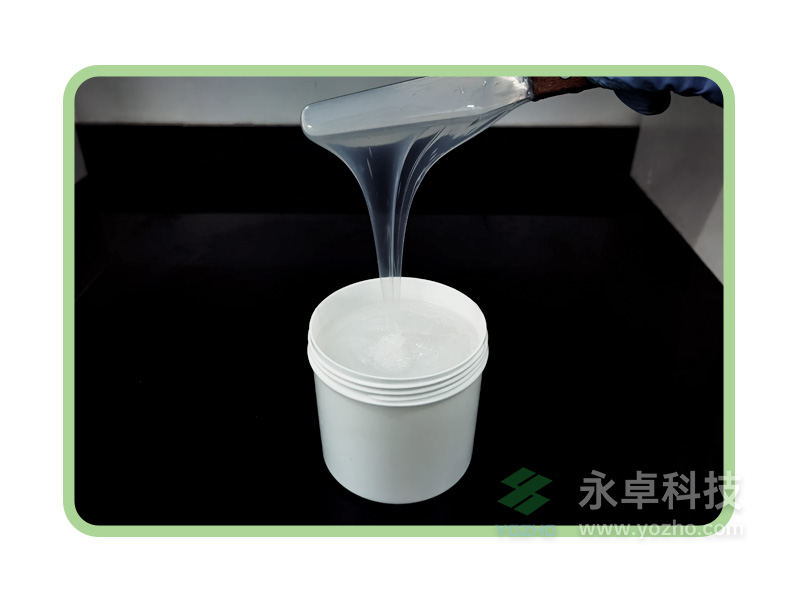

Condensat ion mold s i l icone: 2818#

Colour:translucent

-

Introduction:

Mold silicone rubber, commonly known as silicone, is a two-component product. Its vulcanization can be carried out at room temperature or high temperature. As long as the two components are mixed in a certain proportion (the specific proportion can be determined according to the operation time and product properties), the compound will crosslink to form a flexible, elastic colloid. It can be used to make excellent elastomers with different hardness and tear strength, applicable to casting and brushing processes. Products after the operation have a stable size, minor line shrinkage rate, and the operation is not limited by the thickness of the product. Deep curing is also achievable, and there is no deformity when heating in a sealed environment. Additionally, the crosslinking reaction is a non-exothermic process without low molecular weight by-products released. Beyond that, it has the characteristics of excellent high-temperature resistance (200-300℃) performance, high tensile resistance, high tear resistance, and more mold repeated-use times. It can better avoid problems such as mold burning, surface drying but moist inside, poor tensile force, non-resistance to acid, alkali, and aging, etc.

-

Features:

Eco-friendly and non-toxic, low viscosity, easy operation, easy defoaming, low shrinkage rate, long service life, good elasticity, tensile resistance, swelling resistance, good resistance to acid, alkali, high temperature, aging, and deformation.

-

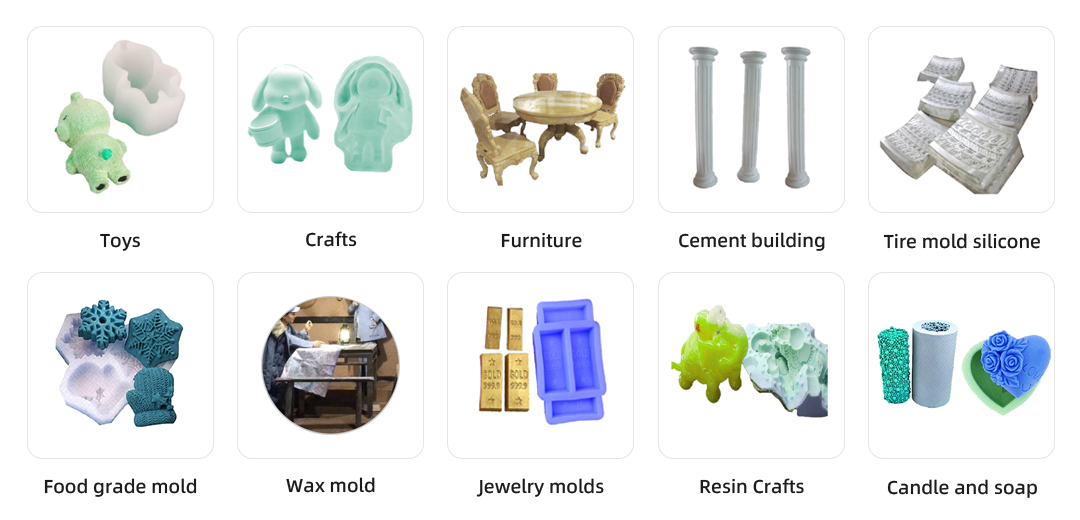

Application:

The addition/condensation mold silicone produced by Yozho Technology is widely used in fields such as gift toy, craft gift, furniture decoration, cement and gypsum, replica candle, resin handicraft, mold manufacturing, animal and plant sculpture, wax figure and Buddha carving handicraft, epoxy resin, polyurethane, unsaturated resin and other handicraft production.