How to solve the problem of silicone potting glue poisoning and not curing? A brief discussion on common problems and countermeasures of silicone potting glue

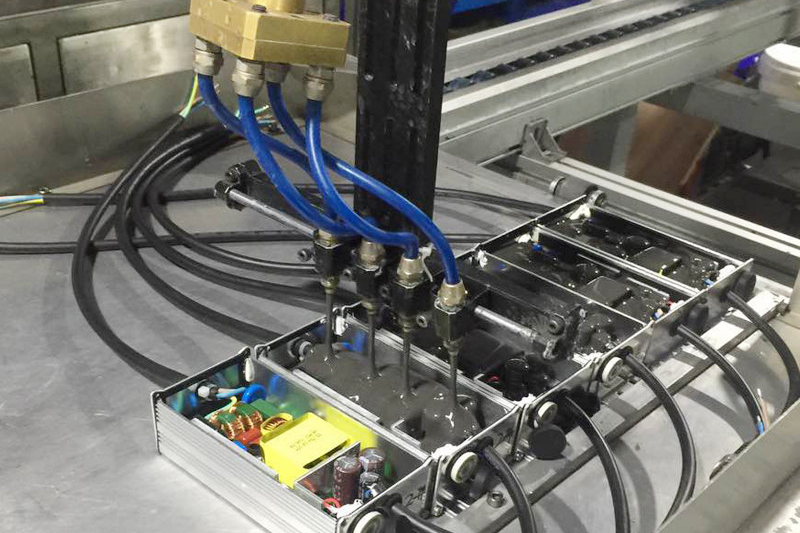

In the electronics industry, after curing, potting adhesive can effectively protect electronic equipment products, playing a role in waterproofing, moisture-proof, dustproof, insulation, heat conduction, anti-corrosion, and high and low temperature resistance. Organic silicon sealant has been widely used in fields such as power supply, lighting, inverters, and automotive electronics.

During the use of silicone sealant, we often encounter some problems. Today, we will briefly review and provide countermeasures after encountering these problems.

Silicone potting glue

1. How to solve the problem of silicone potting glue poisoning and not curing?

Silicone potting glue will be poisoned when it is used. The "poisoning" at this time does not mean that people will be poisoned, but that the silicone potting glue will not solidify. This situation is called poisoning, so don't misunderstand it. .

The mechanism of silicone potting glue poisoning

1. Non-metallic elements and their compounds in groups VA and VIA in the periodic table (such as element compounds of S, N, and P). These elements or compounds have lone pairs of electrons, which are easy to combine with the d orbital electrons of platinum metal to form strong adsorption bonds, which poison the platinum catalyst.

2. Poisons with unsaturated bonds: The principle of poisoning is that the electrons on the π bond enter the d orbital of Pt, reducing the d hole of Pt.

3. Metal or metal ions: For example, when Au and Pt interact, the electrons on the S in the inner and outer layers of Au fill into the d orbitals of Pt, reducing the d holes of Pt.

Poisoning of silicone potting glue generally occurs in addition-type electronic potting glue. After poisoning, the silicone potting glue will not solidify. Therefore, when using addition-type potting glue, avoid contact with organic compounds containing phosphorus, sulfur, and nitrogen. Contact with compounds, or use polyurethane, epoxy resin, unsaturated polyester, condensation room temperature vulcanized silicone rubber and other products together with addition silicone to prevent poisoning and non-curing.

Silicone potting glue

2. What can I use to clean the silicone potting glue that has been accidentally stuck?

Commonly used silicone cleaning agents mainly include alcohol, acetone, liquor, etc.

3. What should I do if the silicone potting glue cannot dry in winter?

Because the temperature in winter is very low, the electronic potting glue cures very slowly or even does not cure for a long time after mixing. Therefore, we can increase the curing temperature and place the glue-filled product in an oven at 25°C or higher for curing.

4. What are the advantages and disadvantages of silicone electronic potting glue compared to other potting glues?

Advantage ①: Provide long-term protection for sensitive circuits or electronic components. It can provide long-term and effective protection for electronic modules and devices, whether they are simple or complex structures and shapes.

Advantage ②: It has stable electrical insulation properties and is an effective barrier to prevent environmental pollution. After curing, it forms a soft elastomer that can eliminate the stress caused by impact and vibration within a wide range of temperature and humidity.

Advantage ③: It can maintain its original physical and electrical properties in various working environments, resist degradation by ozone and ultraviolet rays, and has good chemical stability.

Advantage ④: It is easy to clean and dismantle after potting so that electronic components can be repaired and new potting glue can be re-injected into the repaired parts.

However, silicone potting glue also has two disadvantages:

① The adhesion is poor. When used as a potting or coating material, in order to improve the adhesion with the basic substrate, it is usually necessary to pre-prime the substrate or add a tackifier to modify it. More troublesome.

②Easily poisoned (not cured). Silicone potting glue is a relatively environmentally friendly potting glue. Platinum curing agent is relatively active and can easily react with other impurities to cause poisoning.

Potting glue

5. What is the difference between addition type potting glue and condensation type potting glue?

The biggest difference between addition-type potting glue and condensation-type potting glue is that the condensation type has small molecular substances, while the addition type does not. This determines the difference in their performance.

Addition type room temperature potting glue is cross-linked by the addition reaction of silicon hydrogen bond and ethylene double bond under the action of platinum catalyst. No small molecules are produced during the reaction process; condensation room temperature potting glue is made of silica gel and ethylene double bond. In the presence of a catalyst, the active groups of the curing agent condense and release small molecules for cross-linking and curing.

Tags for this article: Silicone potting glue